Laser micro processing

Laser micro processing

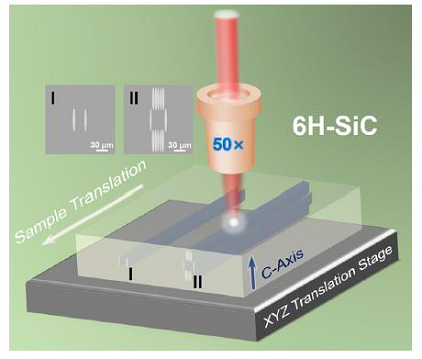

Precision processing of surfaces and materials with lasers is being referred to as laser micro processing. Related applications are micro structuring, micro drilling, fabrication of functional surfaces, fine-edge blanking, marking & trimming.

Features of laser material processing vs. traditional methodes at a glance:

- High flexibility and therefore also small production batches economically justified

- Very low heat inductance

- Ablative process without volume damage

- Cutting edges in micrometer range feasible, almost no post-processing required

- Engraving, marking and cutting with the same laser source in one workstep possible

- Contact-free and very low-wear processing

There are good reasons for ultrashort pulse lasers:

EQ Photonics is offering pico- and femtosecond-lasers from chinese manufacturer YSL Photonics.

- High efficiency and therefore low cooling demand

- Fiber lasers are very compact and almost maintenance free

- The transport of the laser beam to the process optic is via a very flexible process fiber and doesn’t need deflection and positioning optics

Following some very particular application which can be realised by using ultrashort pulse fiber lasers:

- Cutting (OLED / PERC Solar cells / FPC / PCB / monitor / silicium / battery foil / SiC / metal)

- Drilling (semiconductor / FPC / PCB / ITO / thin film / glass / saphire)

- Structuring (ITO / semiconductor / glass / saphire / thin film solar cells)

- Ablation (silicium, semiconductor)

- Marking (black marking, transparente materials, chrome-vanadium)

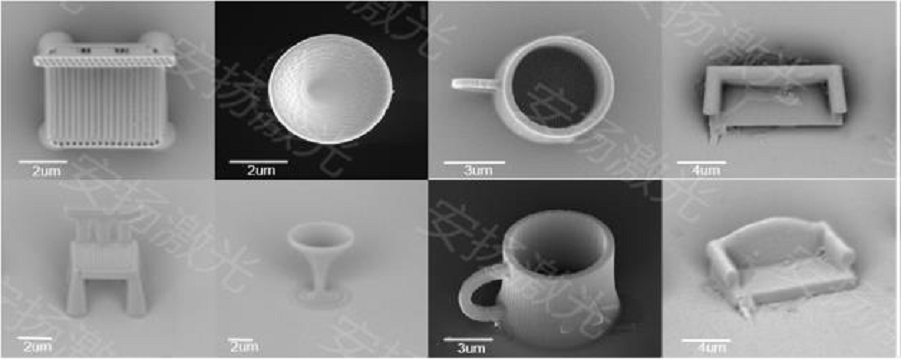

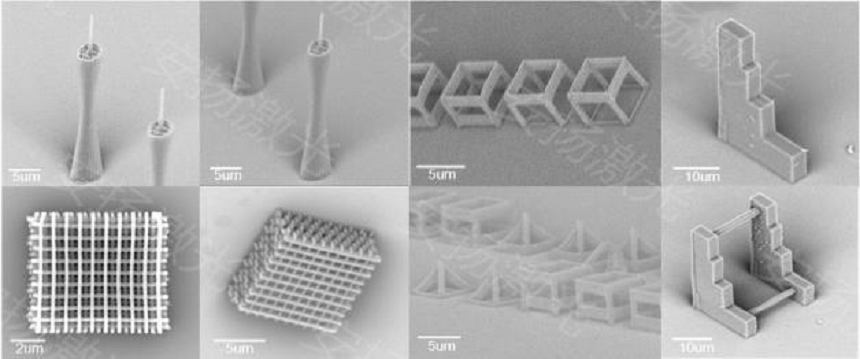

- Two-photon-polymerisation (3D printing)

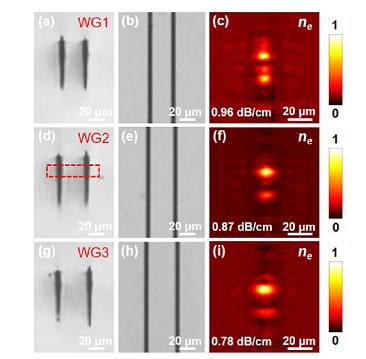

- Refractive-index-modification

- Laser trimming