Laser cladding

Laser cladding

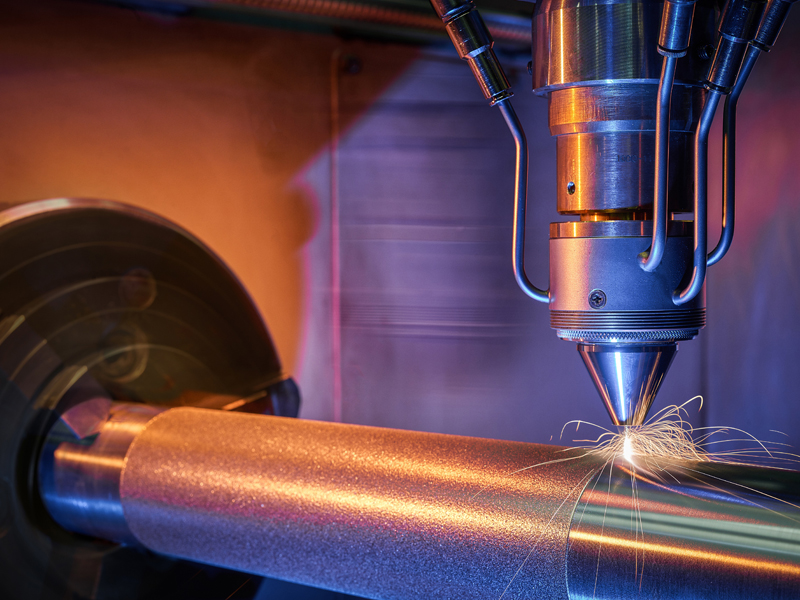

Laser cladding is a method of depositing material by which a powder or wire feedstock material is melted and consolidated by use of a laser in order to coat part of a substrate or fabricate a near-net shape part. The laser can be a CW fiber laser or a high power laser diode. With Maxphotonics and BWT we have two leading manufacturers for this beam sources

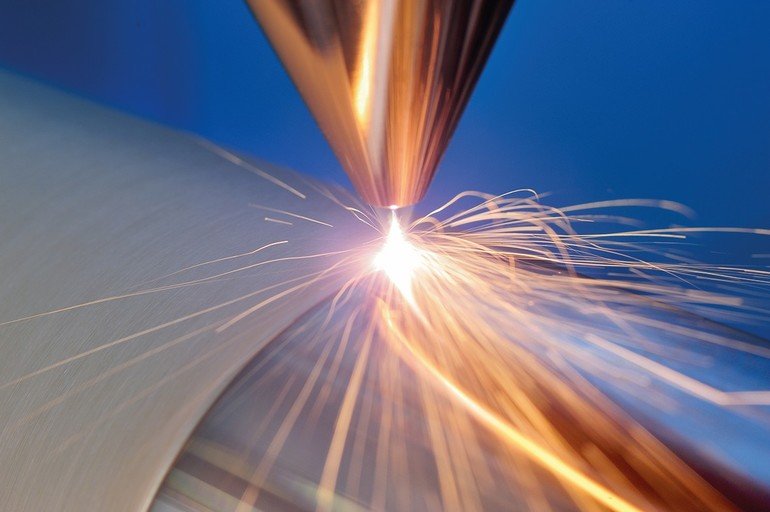

This is how it works: The laser is used to melt metallic powder dropped on a substrate to be coated. The melted metal forms a pool on the substrate; moving the substrate allows the melt pool to solidify in a track of solid metal. Some processes involve moving the laser and powder nozzle assembly over a stationary substrate to produce solidified tracks.

This manufacturing process is mainly being used to repair worn out (big) parts as it is too expensive to exchange them, for example turbine blades etc. Also, surface material may be laser cladded directly onto a highly stressed component, i.e. to make a self-lubricating surface or to increase corrosion resistance.