Laser hardening

Laser hardening

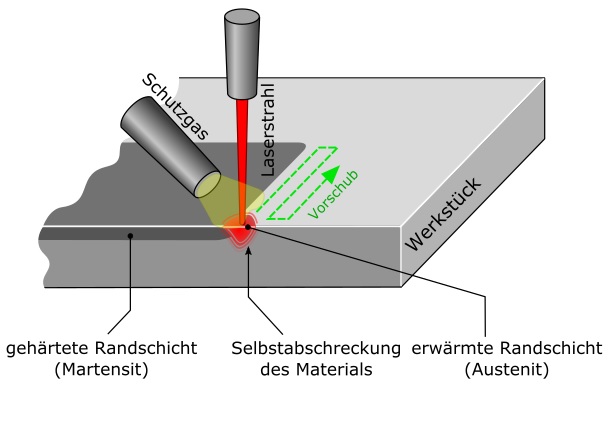

Besides the traditional hardening process, such as flame hardening, laser hardening has many advantages. A selective insertion of concentrated heat by a laser beam onto the material, so that also very small and angulated workpieces can be hardened without post-processing.

According to laser power and the feed rate the workpiece will be hardened below melting temperature in order to increase component strength.

As also for the other laser material processing applications a high absorption rate is important for an effective laser hardening process. A CW fiber laser in infrared wavelength range is the best choice for any kind of metals.