Laser Systems

High Standards. Precise Solutions.

Your Laser System – Realized with EQ Photonics.

When your requirements demand more than standard solutions:

- Access to a wide range of laser sources and laser components

- Technology-independent consulting focused on your application – not on individual products

- Feasibility testing included for your specific application

Jihui Song – Sales & Business Development Manager Laser Solutions

Typical challenges when selecting industrial laser systems

High performance requirements, but no suitable laser system available

Limited selection of wavelengths for special materials

Unclear or overpriced pricing structures from established suppliers

Lack of consulting at eye level – products instead of solutions

Project delays due to slow response times or rigid system configurations

Limited adaptability for experimental setups and new concepts

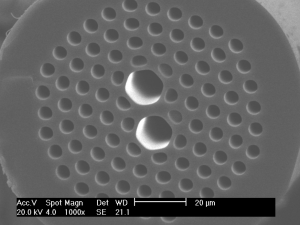

Laser-Microprocessing

Laser microprocessing involves the use of pulsed laser sources with minimal thermal impact, enabling fine and highly precise machining of heat-sensitive materials. Ultrashort pulse lasers—especially femtosecond lasers—are particularly suitable, as they generate extremely short pulses through mode-locking and achieve significantly higher peak powers than continuous-wave lasers.

The range of applications spans from medical and scientific uses to industrial processes. Typical examples include cutting (sapphire) glass for mobile devices, metal marking, inner-glass engraving, and precision machining of implants and medical instruments.

To meet the growing demand, EQ Photonics has been working successfully with YSL Photonics, a manufacturer offering a broad portfolio of femtosecond and picosecond lasers in various power classes and wavelengths (IR, green, UV).

Laser-Macroprocessing

Laser macroprocessing refers to the use of high-power continuous-wave (CW) laser sources that deliver constant intensity. Key applications include laser cutting, welding, cladding, hardening, and additive manufacturing processes such as selective laser melting with metal powders or selective laser sintering of plastics.

Core components of a laser processing system include the laser source and the process optics that focus the beam. Fiber lasers have been widely used for many years due to their high efficiency, excellent beam quality, long lifetime, flexibility through the process fiber, and low maintenance requirements.

These advantages are embodied in the CW and QCW fiber lasers from Maxphotonic. As complementary components, we also offer cutting and welding heads from RayTools as well as reliable laser chillers from S&A.

Technology-Open Consulting: We Find Solutions for Your Requirements

As a Photonics Solution Provider, EQ Photonics guides you to the right laser system solution – with technology-independent consulting, one of the broadest portfolios on the market, and a clear focus on your project success.

Laser Systems of the Highest Quality

From precise diode and fiber lasers to high-performance systems for industry and research – EQ Photonics offers the ideal laser source for every application in material processing, metrology, or science.

Laser Optics for Maximum Efficiency

Whether for beam shaping, focusing, or collimation – EQ Photonics provides high-quality laser optics and assemblies that significantly improve the performance, stability, and precision of your application.

Focus on Research & Development

From basic research to applied photonics – EQ Photonics delivers laser systems that stand out through stability, adaptability, and superior beam quality. Ideal for precise experiments and laboratory applications.

Our lasers and optic components at a glance

What customers have achieved with our cameras: Examples from the field

Cutting Carbon Fibers with a 2-μm Laser

Precision Redefines Performance

Use case: Precise cutting of carbon fibers for high-performance composite materials

Key result: Maximum efficiency and precision through 2-μm fiber laser technology with micrometer-accurate cutting performance

Our service: Provision of a scalable laser cutting system with digital process control and reproducible accuracy of < 0.05 mm

Carbon fibers are the backbone of modern lightweight construction, but cutting them requires the highest precision.

With the 2-μm fiber laser from GW Laser, an efficient serial process has been developed: laser focus points in the micrometer range enable smooth, clean cuts without tool wear or burr formation.

The system achieves repeatability in the sub-micrometer range and can process hundreds of kilograms of fiber per hour – ideal for the automotive, aerospace, and manufacturing industries.

The result: higher process stability, improved bonding quality, and reduced production costs – a milestone for the next generation of lightweight composite materials.

Versatile CO₂ Lasers for Maximum Process Control

Super-pulsed precision for demanding manufacturing processes

Use case: High-precision processing of plastics, metals, textiles, and thin films

Key result: Combination of super-pulse and quasi-CW modes for maximum flexibility between pulsed and continuous operation

Our service: RF-excited metal-slab CO₂ laser with configurable pulse frequency (1–50 kHz), fast pulse modulation, and stable beam quality

Through short high-intensity pulses, the material is efficiently penetrated without causing thermal overload.

The technology enables very fine engravings as well as high-speed processing with consistent quality.

Ideal for OEMs seeking precise, reproducible results in industrial applications.

Precision for OLED Technology

Femtosecond UV Laser Technology for Maximum Quality and Efficiency in Display Manufacturing

Use case: High-precision cutting and structuring of glass substrates in OLED production

Key result: Ultrashort-pulse technology with femtosecond UV lasers for micrometer-accurate processing, minimal thermal influence, and significantly reduced defect rates

Our service: Integration of YSL femtosecond UV lasers into existing production lines — including process optimization, real-time validation, and around-the-clock technical support

By implementing YSL femtosecond UV lasers in the OLED production lines of Tianma Microelectronics, a new level of quality was achieved:

Defect rates were halved from 0.02% to 0.01%, maintenance costs per line were reduced by more than €120,000, and delivery times were shortened by over 50%.

The ultra-short pulse duration enables precise, clean cuts even in sensitive materials like thin glass — without thermal stress or particle generation.

Thus, YSL Laser supports reliable mass production of over one million OLED panels and strengthens the technological independence of the display industry.

This is what you can expect from us and our laser solutions:

Reduced project durations and faster marketability

EQ Photonics accelerates your automation projects with short response times, modular machine vision components and individual advice. This enables us to rapidly deploy solutions into production enviroments – especially in mechanical engineering, intralogistics and quality assurance.

Technological independence through open systems

The technological capabilities of industrial image processing are especially valuable for companies in special machine construction, robotics, and automation. EQ Photonics offers scalable, open vision systems – from smart cameras to 3D vision – that are modular, expandable, and compatible with a wide range of technologies.

Sustainable investment through a scalable solution

With modular VisionMaster software, optional AI integration and high-performance camera components, EQ Photonics enables long-term perspectives for growing requirements – e.g. in high-speed inspections or track & trace applications.

Who we are: EQ Photonics is your partner for lasersystem solutions

EQ Photonics is your partner for innovative laser technologies.

We create connections between leading photonics expertise and the demands of modern industrial and research applications.

Whether high power, precision, or flexibility – EQ Photonics delivers technology-open laser solutions that are perfectly tailored to your application.

Cross-manufacturer consulting, modular system architectures, and customized project support ensure that you receive exactly the laser system that optimally supports your process.

.

| Manufacturer | Online-Shops | EQ Photonics | Integrator | |||

| Expert advice on customized solutions | ✓ | – | ✓ | ✓ | ||

| Integrated solutions from a single source | – | – | ✓ | ✓ | ||

| Single point of contact for all matters | – | ✓ | ✓ | ✓ | ||

| Access to research and development, product management and production | ✓ | – | ✓ | – | ||

| On-site training and support | ✓ | – | ✓ | ✓ | ||

| Delivery of small batches | – | ✓ | ✓ | – | ||

How to start your laser project with EQ Photonics

1. 30-minute initial consultation

2. Requirements analysis and application-specific advice

3. Joint feasibility test

4. Proposal phase and project start

5. Delivery, integration and support

Why does EQ Photonics rely on GW Laser?

EQ Photonics has been working with the manufacturer Hikrobot since 2024: Hikrobots products impress with their technological substance, attractive price structure and versatility in industrial image processing solutions.

Particularly relevant from a customer perspective:

Long-term availability – important for series production

Wide variety of lasers for different applications

Excellent price-performance ratio for laser systems and components

High integration capability thanks to open platform architecture

Scalability for growing technological requirements

Frequently asked questions about EQ Photonics laser solutions

The exact requirements depend on the specific application: whether you need high power, precise beam quality, or compact designs – we provide open-technology consulting and work with you to find the ideal laser system for your application.

Thanks to the wide range of wavelengths, pulse durations, and power levels, laser systems can be precisely adapted to specific applications – from fundamental research to series production. They open up new possibilities in areas such as materials research, medical technology, and additive manufacturing.

The price depends strongly on project scope, accuracy requirements, and system complexity. As a rule, we provide a rough price range even before the feasibility study.

We analyze your application, review the technical requirements, and, if necessary, simulate the setup. The goal: to provide clarity about feasibility and system design before you invest.

We see ourselves as a genuine alternative because we combine German quality standards and technical precision with the cost efficiency and flexibility of our partners in China. The result is an exceptional price-performance ratio that unites technical excellence with economic attractiveness.

Instead of standardized sales processes, we focus on personalized consulting, technical expertise, and tailored solutions – from the first idea to final implementation.